How To Wire a Dual Battery System Into Your Vehicle

Overview

How do you Hook Up Dual Batteries?

If you're set on a second 12-volt battery in your vehicle to run extra accessories, you'll need to understand how to wire up an auxiliary battery into the system without compromising the cranking battery performance.

The auxiliary battery will need to be charged via the alternator/solar system with the ability to be cut from draining the cranking battery when in use to avoid draining it flat and leaving you stranded.

Learn about dual batteries.

Learn about battery boxes.

Learn how solar panels work.

Learn how about VSR chargers.

Learn about trailer wiring.

Learn about battery maintenance.

Learn about battery chargers.

What Cable do I Use for Dual Batteries?

To understand what size cable you need for your new battery, you'll need to calculate the correct cable gauge (thickness) vs length vs voltage drop. To do this, you'll need to measure the length of cable you require to your VSR or DC to DC Charger and note the amp rating required to determine the cable diameter needed to carry the load. There's several wire gauge calculators online and in the app store if you need an easy solution.

The wires provided in most VSR Kits are suited to the amp rating on the VSR and length provided. It is best practice to double-check that you won't deal with a voltage drop problem for your battery and accessories.

What does Supercheap Auto Stock?

- VSR Kits - If you have a battery installed for solar use, wy not have the vehicle charge it while you drive with a Voltage Sensitive Relay.

- Battery Boxes - Keep your deep cycle battery stored away in a battery box for peace of mind.

- Deep Cycle Batteries - If you're planning a dual battery setup, you're going to need a deep cycle battery that's designed to be drained.

- Solar Panels - Keep your batteries charged without your vehicle running with a solar setup.

How do you Wire a VSR?

A basic setup for a dual battery system is an isolator kit or voltage-sensitive relay kit (VSR for short) which is suitable for under-bonnet installations on most vehicles before 2010. This uses a voltage sensing relay that charges the second battery using the alternator and cuts off the connection to the cranking battery when it drops below 12.8 volts. These are often purchased as a kit including the correct size wiring, and all the ring terminals you'll need. However; some VSRs are supplied without a wiring kit – you'll have to purchase some extras to make it work for you.

Once you have the best to mount your VSR, up high or on the firewall is a common location. Basic VSR wiring needs only three wires connected; main battery power, second battery power, and a much smaller earth wire for the VSRs internal functions. We have great How To Install a VSR Guide you can check out if you want step by step instructions.

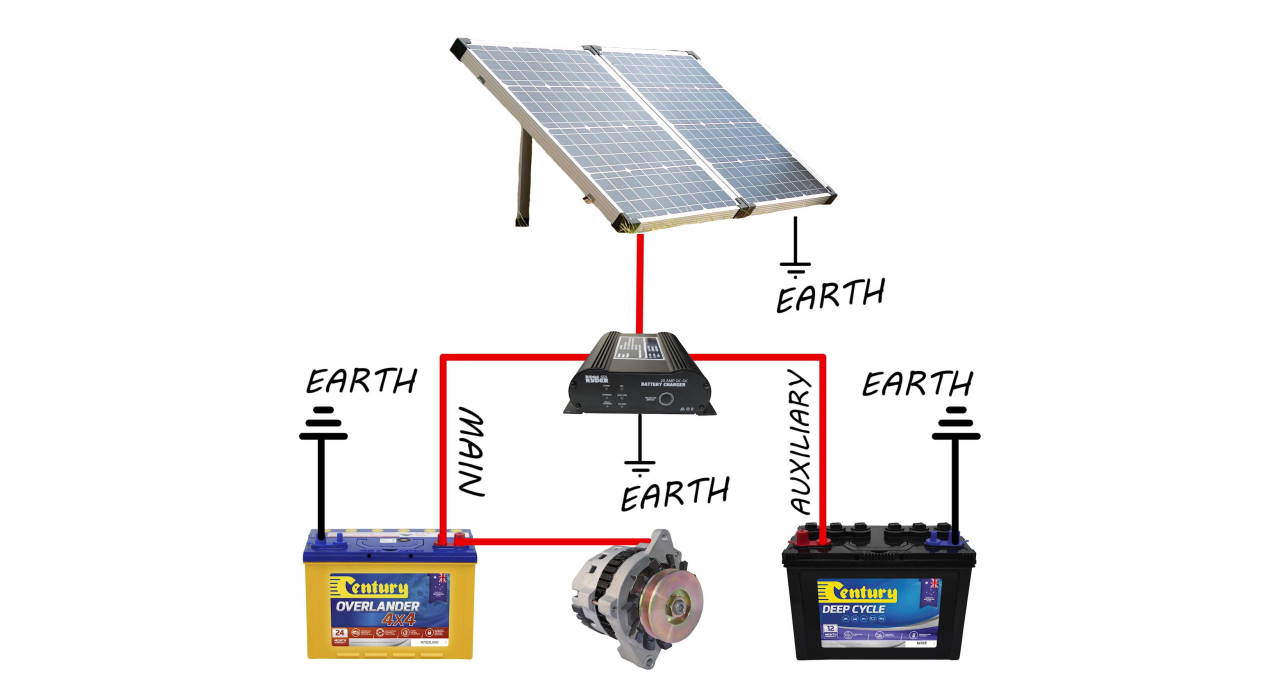

How do you Hook Up a DC to DC Charger?

A DC to DC Charger is what you'll need for many later model vehicles fitted with a factory smart alternator – or cargo area installations which is perfect for Campervans and SUVs. Power comes from the main battery entering the charger through one cable and heading to the auxiliary battery after being converted for an optimised charge. There will also be an earth cable for the unit, possibly a solar power input, a trigger wire and sometimes a battery temperature sensor to monitor the health of the secondary battery. The trigger wire is important for smart alternator vehicles. Tap this into an ignition feed to ensure your auxiliary battery only charges while the engine is running.

Mount your DC charger as close to the auxiliary battery as possible. This ensures less potential for voltage drop and delivers maximum charge. They don't like heat either – so keep it away from the exhaust with as much airflow as possible. While a DC to DC charger is not normally supplied with all the cables required; there is no need to calculate a specific cable gauge, as these units will compensate for voltage drop. Check the user manual for the recommended cable diameter - and plan the lengths needed for your install.

What Else do I Need for the Install?

You may need to grab a few extras to complete your installation. Pick up enough cable lugs to terminate your cables. A DC to DC charger installation will require circuit breakers or fuses at both batteries as well. Cable ties, corrugated split tubing, heat shrink, electrical tape, cable ties, a soldering iron and, some solder will help you round out a perfect job.

It is wise to leave battery terminals disconnected throughout your install, to prevent short circuits. Make sure all cable terminals are crimped tightly with a lug crimper. Cable joins at a DC charger can be soldered or crimped - and covered with heat shrink. Check out our how to solder guide - and do it like a pro.

Wrap each cable with corrugated split tubing, and heat shrink the terminal ends. Every piece of wiring should be secured as you go with cable ties. Finally, bolt up all the terminals – leaving the earth cables for both batteries till very last. Your VSR or DC charger should do nothing until the engine is running. To test its performance, check the user manual for the cut-in voltage.

With the engine running, your VSR should click in at this voltage, and a DC to DC charger should display 'charging'. Turn the engine off, and when the voltage drops to a pre-set level – your two batteries will be separated. For solar charging, trailer installations and much more; tune in to further episodes of the Supercheap Auto Battery Fundamentals series.

Steps

*Important information* - Click here to read more about our How-To terms and conditions.