How To Remove a Snapped Screw/Bolt

Overview

So you’ve snapped a bolt in the engine block. A worrying issue at first, but with help from the range of screw and bolt extractor sets from Supercheap Auto, you’ll have it fixed in no time.

Here’s how it’s done.

Steps

Marking Screw/Bolt

Start the job by marking the centre of the snapped bolt with a centre punch, so the drill bit doesn’t walk.

Preparation of Equipment

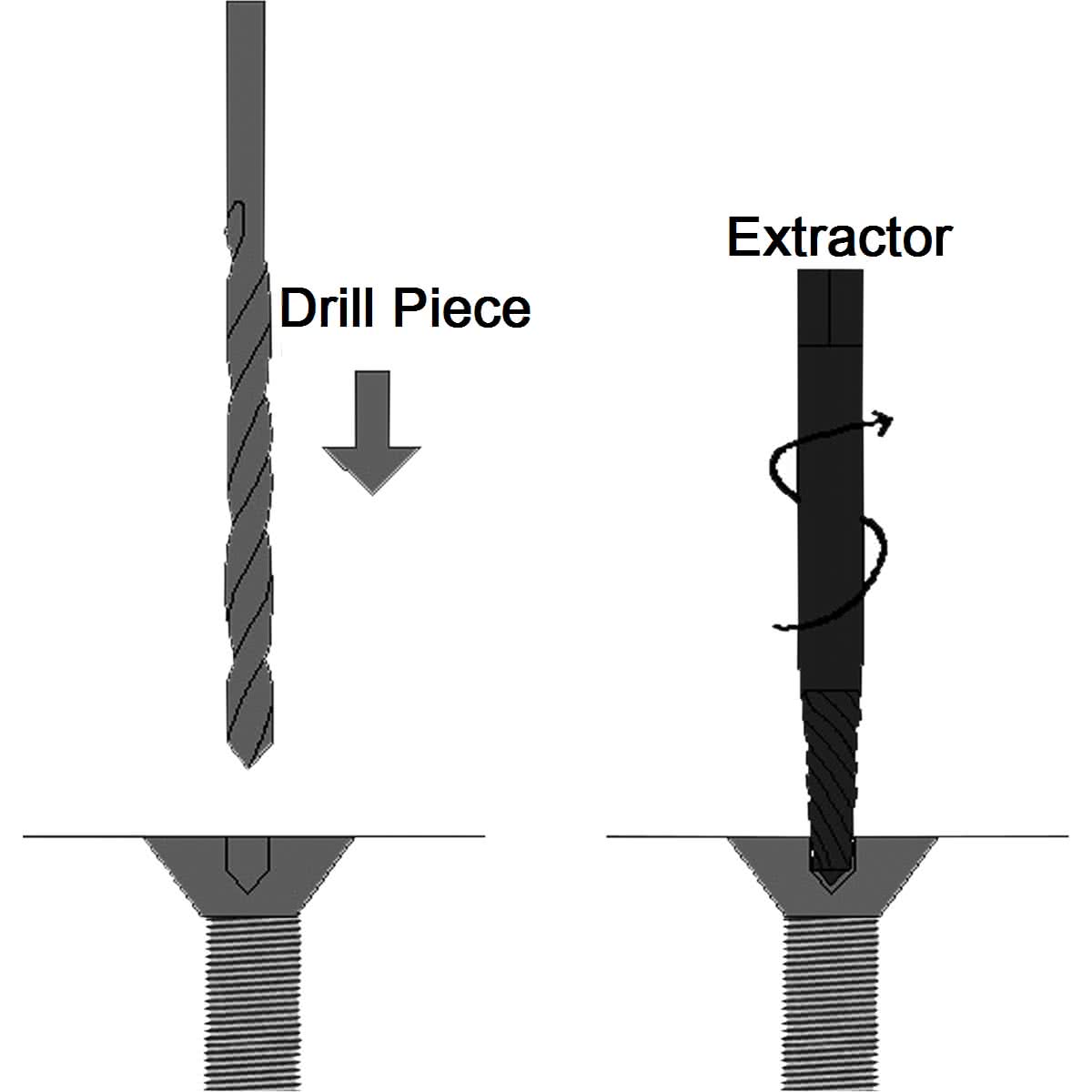

Choose an extractor from the kit as close to the bolt size as possible - that won’t ruin the thread on the sides; and drill a hole in the centre of the snapped bolt.

Start with a small drill bit, and work your way up to the correct size for your extractor bit.

Be careful not to hit the sides of the hole and ruin the thread, and only go deep enough to allow the extractor to bite.

Extract the Screw/Bolt

Screw extractors feature opposite threads which are tapered, and lock into the drilled out bolt. The more pressure you apply anti-clockwise, the harder they bite in.

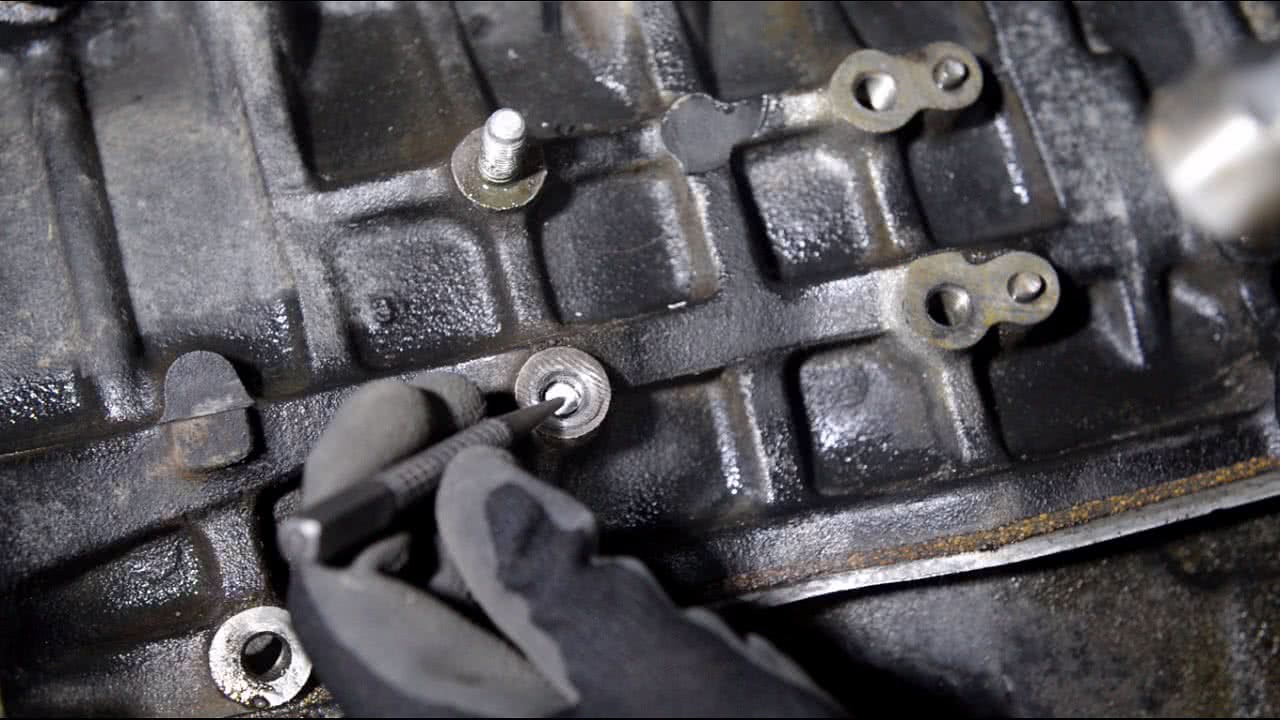

Thread the extractor anti-clockwise using a hand tap, adjustable spanner or locking pliers. The snapped bolt should start to come free with a little pressure.

Removing Screw/Bolt from Extractor

Once the snapped bolt is removed, it can be freed from the extractor using a pair of locking pliers, or a bench vice to spin the broken thread clockwise.

*Important information* - Click here to read more about our How-To terms and conditions.