The humble drill driver is capable of so much more than just drilling the occasional hole. Brush up on your drill driver knowledge and discover the massive range of tasks you can accomplish with one.

Here's how it's done.

Tip 1: Safety

Before you start, you'll need safety equipment:

- A decent pair of gloves

- Clear eye protection

- Ear protection

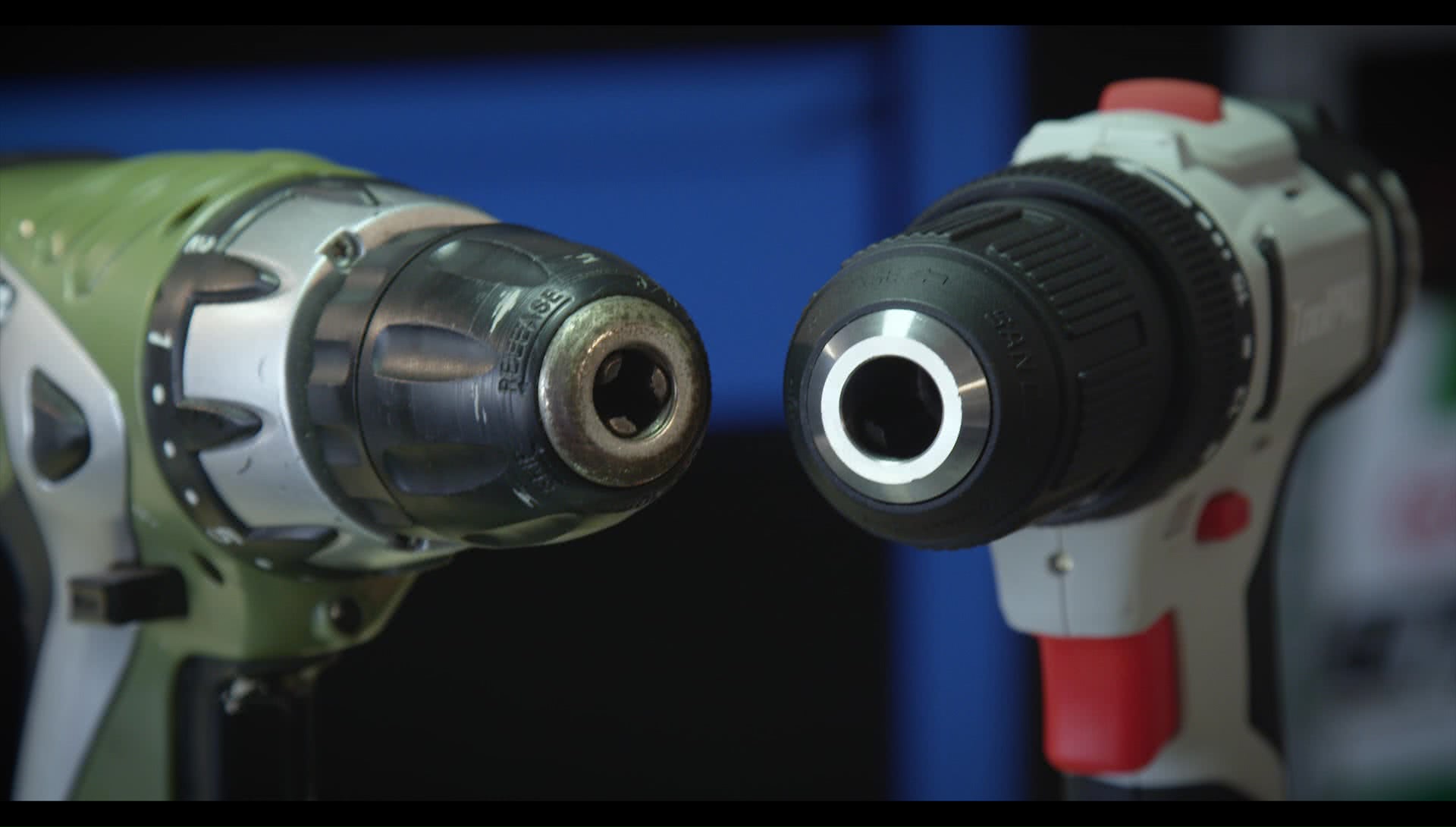

Tip 2: Chuck and Bits

A drill driver is typically available with a 10mm or 13mm chuck, the larger of the two being more versatile.

What you install in the chuck depends on the job to be done; a high speed steel drill bit serves to drill holes in most metals and wood, a hole saw is great for cutting large holes in these materials too.

There are tile and glass bits, Philips, flat heads, and hex bits for fasteners - or spade and countersunk bits for woodwork.

Once you have installed the bit into your chuck, there are ranges of selectable settings appropriate to the task.

Tip 3: Speed

First of all, select the drill speed, a choice between two on some drill drivers.

The higher speed is perfect for drilling most materials, while the low speed should be selected for affixing fasteners or working with certain metals.

Tip 4: Settings

For most drilling operations, the torque adjuster should be set to ‘drill’ mode, or the highest number on the adjustment ring.

To accurately drill a hole, first mark the location with a centre punch. If the desired hole is to be less than 5mm in diameter you can usually go straight to the size required.

However, larger holes should have a pilot hole drilled first, working your way upwards from there. This does not apply to hole saws or spade bits.

If you are using the drill driver to insert screws, self-tapping screws, or drive nuts, bolts and other fasteners – the torque should be set just high enough to reach the desired tension before the drill comes to a stop.

Setting the torque too high may result in stripped heads on your fasteners. Set it too low and the drill driver won’t insert the fastener all the way.

If your drill bit gets stuck, or you need to remove a few fasteners - just flick the forward reverse switch – usually located right near the trigger.

Tip 5: Precautions

Last of all, there are a few jobs best avoided with this type of drill. While your drill driver will accept a masonry bit, they commonly lack a hammer function.

Without this hammering action, any masonry drilling will take a very long time – possibly overheating and damaging the drill bit or even the tool itself.

While this tool can be used with a hole saw, the clutch inside the torque mechanism is susceptible to damage with larger hole saws over 25mm.

The drill driver is the all-rounder of power tools, this capable and adaptable unit is usually and rightly so, the first drill to call your toolbox home.

*Important information* - Click here to read more about our How-To terms and conditions.