Most passenger cars on the road today are powered by petrol. Whilst this may change in the future, in the meantime it is a good idea to understand a few of the basics of how the petrol fuel system works, as well as what you can do to ensure that your car runs efficiently and with optimal power output. In this article we are going to cover a basic overview of how your fuel system works, a few of the most commonly encountered components of the system and how they work, and finally what tools you are likely to require when working on your fuel system in a petrol car.

How does a Combustion Engine Work?

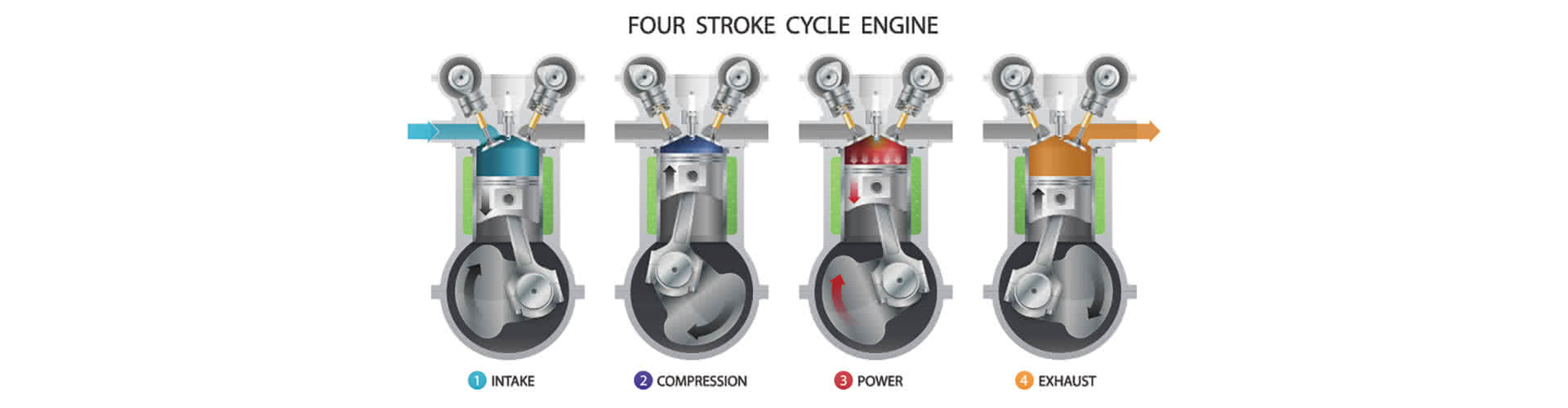

The three main things that a petrol car requires to function are air, fuel and spark. We have already covered the first and last of those, so let’s look at fuel and it’s role in the process. When you turn the key and crank the engine over, the starter motor will turn the flywheel and thus the crank - making the pistons travel up and down through their bores. Each piston on a four-stroke motor has four things it may be doing (hence the term) dependant on which valves are open or closed and whether the piston is moving up or down: Intake, compression, ignition and exhaust. During the intake stroke, the piston will move down in the bore and the intake valve will be opened to allow an air/fuel mixture to be drawn into the cylinder.

In most cars, turning the key to “ON” will energize the fuel pump, to allow a flow of fuel into the injectors via the fuel lines that run from your tank to the motor. The injectors will then fire the fuel into the combustion chamber in an incredibly fine mist during the intake stroke, and this air and fuel mixture will then be compressed and ignited in the following compression/ignition strokes. Once the motor has fired on one or two cylinders, it’ll generate it’s own momentum and keep rotating the crank, moving the pistons, and injecting fuel etc. until either fuel or ignition is cut off by switching the key to “OFF.”

Types of Fuel Delivery

In modern vehicles there are a few different ways that fuel can be delivered into the motor for combustion, though they all fall within two main categories.

What is a Carburettor?

The first and oldest of the two setups are those that use a carburettor (Commonly called a “carb”, “carby” or “carburetor” if you are American.)A carburettor essentially consists of a pipe that delivers air into the intake manifold of the engine, little openings that supply fuel to this pipe, and valves that open or close to increase or limit the amount of air that can flow through the pipe and thus draw fuel in too.

The pipe itself is made in the shape of what is called a “Venturi” - it narrows down and then widens back out, to increase airflow over the narrow section. Some carburettors have fixed-Venturi systems, which means that the air pipe is manufactured to be a specific shape, whereas others utilise moving components to adjust where the pipe is narrowest. These are referred to as “Variable-Venturi” and can range from fairly simple to extremely complex.

In addition to the Venturi, the carburettor will also have a system for introducing fuel into the air-flow at various points. These take the form of precisely sized tubes called “Jets.”

Carburettors utilise the air flow to adjust the amount of air/fuel mixture delivered to the motor, but delivery of fuel to the carburettor is equally as important. This is handled by the fuel pump, which sends the fuel into a little reservoir in the carburettor called the “float chamber” or “bowl” where it is readily available to be drawn into the intake as required. There is usually a device that will float in the fuel and control a valve that allows fuel to fill the bowl up - it works pretty much exactly like the cistern in your toilet.

How does a Fuel Injection System work?

Most modern car manufacturers have moved away from carburettors in favour of fuel injection systems. The reason for this is that computer-controlled injection can limit over-fuelling and therefore increase efficiency, as well as reducing emissions.

Early injection systems weren’t computer operated however, and instead relied on complex mechanical setups to deliver fuel directly into the combustion chamber (direct injection) or into the intake (indirect injection.)

As with many major changes to motors, fuel injection was popularised in wartime - being necessary to ensure constant fuel delivery to the engines of warplanes when maneuvering or flying at high altitude.

The Germans developed systems for their planes and continued to use mechanical fuel injection on many of their road cars, such as Mercedes-Benz, Porsche and BMW vehicles, whereas the Americans and the British were somewhat slower to adopt the technology outside of military use, and instead only widely used it in racing.

It was only with the advent of Electronic Fuel Injection or EFI systems that fuel injection became the mainstay, since it reduced the complexity of the system by eliminating mechanical systems that required countless finicky parts and incredible expertise to balance, maintain and setup.

Modern fuel injection systems generally consist of the fuel injectors themselves, a fuel pump and fuel pressure regulator, as well as an engine management system that relies on various sensors and relays to measure how much fuel is required and meter out the correct amount in any given situation. Usually the sensors will be an airflow sensor to measure flow into the engine, a crank angle or cam position sensor to figure out where in the stroke the fuel should be delivered, and an exhaust gas sensor to detect the levels of unburnt fuel in the exhaust and allow for adjustments to the air/fuel mix on the fly.

Components in the Fuel System

Many components are common across both fuel delivery systems. All cars will have some sort of tank that holds fuel, as well as lines that deliver the fuel to the motor. Both the tank and the lines should be free from corrosion and damage, as either can inhibit fuel flow or lead to potential fire hazards.

Driving the fuel delivery will be a fuel pump - whether mechanical or electric, and there is usually a filter placed in the lines between the tank and the motor.

Many cars will have an in-tank fuel pump. As the name suggests, this sits inside the fuel pump and will more often than not have a filtering device attached to it as well. In-line fuel filters are usually cheap and easy to replace, and should be checked for blockage and fouling if there are any issues with fuel delivery, as a first step.

It isn’t too much work to replace any of the commonly shared components, and simple tools can be used to do so - however with regards fuel lines, it is important that any custom or replacement lines be up to fuel-bearing standard and be fitted with appropriate connectors to reduce the potential for dangerous leaks.

Common tools used when working on fuel systems

Whether dismantling a carburettor, removing injectors, replacing a fuel filter, or tightening leaking connectors on a fuel line, one of the most commonly used tools is the humble spanner. Spanners and socket sets are invaluable tools for any would-be mechanic, and so should remain the backbone of your arsenal. Another commonly required tool is a decent screwdriver set. You may find that most automotive manufacturers fit their cars with clamps that require a screwdriver to loosen, though there are also pinch-type clamps that may require the use of pliers. When working on fuel systems, always wear goggles and gloves to protect your skin and eyes from harmful and painful spills or splash-back. It is also a good idea to get hold of a simple fan setup to ensure decent air circulation, as the fumes from petrol can be somewhat dangerous to inhale. Be sure to use a drip tray if you are doing any work that requires that you disconnect fuel lines, and make sure you keep some shop-rags handy to clean up any accidental spillage, as well as to wipe down any fuel that might run. A useful tool to have is a fuel line disconnect set - these come in a variety of forms, but can all be used to make the disassembly and leak prevention a breeze!

*Important information* - Click here to read more about our How-To terms and conditions.